PAPRO Forg

Processing Overview

・Excellent lubricity is obtained for plastic working of steel and aluminum, such as wire drawing, tube drawing, and cold forging.

PAPRO Forge treatment reduces die wear, prolongs the life of the press die, improves machining speed, and prevents press scratches.

・ The combination of phosphate, aluminum fluoride coating and soap such as sodium stearate, improves the molding speed and molding strength by improving the lubrication performance when forging and press molding steel and aluminum products without oil.

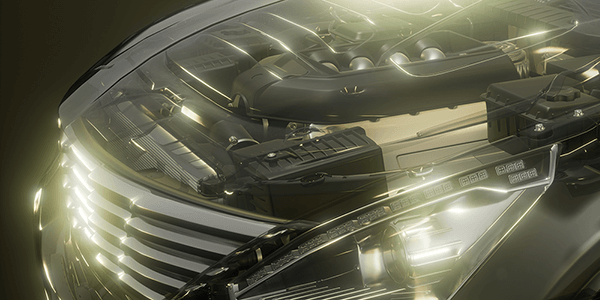

These coatings are used as inexpensive lubricating coatings for automobile interior springs, etc.

PAPRO Forge treatment reduces die wear, prolongs the life of the press die, improves machining speed, and prevents press scratches.

・ The combination of phosphate, aluminum fluoride coating and soap such as sodium stearate, improves the molding speed and molding strength by improving the lubrication performance when forging and press molding steel and aluminum products without oil.

These coatings are used as inexpensive lubricating coatings for automobile interior springs, etc.

・The lubricating layer of the coating is formed by chemical bonding rather than by mere physical adsorption.

In addition, the pre-treatment phosphate is etched into the metal base metal in a pit-like manner, which allows the coating to follow even under severe conditions during plastic working.

Because of the effects of these coatings, even products that cannot undergo plasticity processing with conventional greases can be quickly forged and pressed without seizure or cracking.